ETL-RBL2 - XX ( Flexible Ribbon Led Strip 2-Lines, Non-Waterproof)

Reference Number: ETL-RBL2 - XX (Flexible Ribbon Led Strip 2-Lines, Non-Waterproof)

Description

ETL-RBL2 features 2 line high bightness 3528 SMD Led's on a 16mm (5/8") wide PC board. This roll is ETL Approved

Input 24V DC

Dimmable

98 Watts per 5 meter Roll (16.25') - 6 Watt per foot

1200 pcs of SMD 3528 per Roll (5 meter / 16.25')

Lumen Output:8400 M Per Roll (500 LM Per Foot)

Colors available: ETL-RBL2-WW, (Warm White 3000K), ETL-RBL2-NW (Neutral White 4000K), ETL-RBL2-W (Coll White 6000K)

Special Order Colors: Yellow (ETL-RBL2-YL), Green (ETL-RBL2-GR), Blue (ETL-RBL2-BL), and Red (ETL-RBL2-RD)

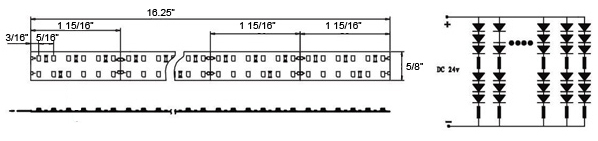

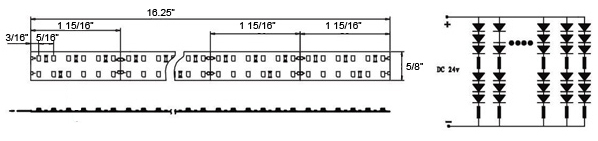

Cuttable: Every 6 Led's (50mm / 1 15/16")

IP RATING: IP20

Product Dimensions

LED drivers available for this ribbon:

Dimmable Magnetic:

FL-60W-24V-LED-DIM1

FL-100W-24V-LED-DIM1

FL-150W-24V-LED-DIM1

FL-200W-24V-LED-DIM1

FL-300W-24V-LED-DIM1

FL-600W-24V-LED-DIM1

Dimmable Electronic:

FL-60W-24V-LED-DIM3

FL-100W-24V-LED-DIM3

FL-150W-24V-LED-DIM3

FL-200W-24V-LED-DIM3

FL-300W-24V-LED-DIM3

Possible applications with ETL-RBL2

Cove lighting

Architectural lights for canopy, corridor, window, archway

Backlight or edge lighting for signage

DIY lights for home use- Path and contour marking

Decorative lights for holiday, event, show, exhibition

Assembly Information

Solder connection should only be performed on designated solder pads. During soldering, don't exceed the maximum soldering time of 10 seconds and the maximum soldering temperature of 260 Celsius degrees.

The smallest unit (50mm - 6 LEDs) can be removed by cutting with scissors between the designated solder pads.

The mounting of the strip is facilitated by means of the double-sided adhesive on the back-surface of the strip.

Care must be taken to provide a clean and dry mounting surface, free of oils or silicone coatings as well as dirt partide.

The mounting substrate must have sufficient structural integrity. Take care to completely remove the adhesive backing.

Once the strip is appropriately positioned, press on the strip with about 20N/cm2 (refer to ap-plication techniques of 3M adhesive transfer tapes).

The minimum bending radius is 2 cm. The strip may be bent over a smaller radius of the circuit board contain-ing no electronic components and such bends should be made once and fixed in position to avoid cyclic fatigue.

Safety Information

The strip itself and all its components may not be mechanically stressed.

Assembly must not damage or destroy conducting paths on the circuit board.

Installation of LED ribbon (with power supplies) needs to be made with regard to all applicable electrical and safety standards. Only qualified personnel should be allowed to perform installations.

Correct electrical polarity needs to be observed. Wrong polarity may destroy the strip.

Parallel connection is highly recommended as safe electrical operation mode.

Serial connection is not recommended. Unbalanced voltage drop can cause hazardous overload and damage the strip.

Please ensure that the power supply is of adapters power to operate the total load.

When mounting on metallic or otherwise conductive surfaces, there needs to be an electrical isolation points between strip and the mounting surface.

Pay attention to standard ESD precautions when installing the strip.

Damaged by corrosion will not be honored as a materials defect claim. It is the user's responsibility to provide suitable protection against corrosive agents such as moisture and condensation and other harmful elements.

Description

Special Order Colors: Yellow (ETL-RBL2-YL), Green (ETL-RBL2-GR), Blue (ETL-RBL2-BL), and Red (ETL-RBL2-RD)

IP RATING: IP20

Product Dimensions

LED drivers available for this ribbon:

Dimmable Magnetic:

FL-60W-24V-LED-DIM1

FL-100W-24V-LED-DIM1

FL-150W-24V-LED-DIM1

FL-200W-24V-LED-DIM1

FL-300W-24V-LED-DIM1

FL-600W-24V-LED-DIM1

Dimmable Electronic:

FL-60W-24V-LED-DIM3

FL-100W-24V-LED-DIM3

FL-150W-24V-LED-DIM3

FL-200W-24V-LED-DIM3

FL-300W-24V-LED-DIM3

Possible applications with ETL-RBL2

Assembly Information

Safety Information